The Diary of a dress design

From design, to production to collection… We follow the step by step process behind everything we do to create our stunning dress range, ‘The Perfect Bridal Collection by Kay Heeley.’

The concept:

Like any idea, brainwave, rush of inspiration, a dress design can come from almost anything. For our designer Kay, it’s more often than not in the fabrics. Once Kay sees a fabric, she can picture the design style it would suit, and the whole design process starts right here.

A self-admitted lover of embroidered fabrics and lace, Kay’s designs always showcase beautiful quality fabrics with exceptional dress making knowledge after 20 years in the bespoke dress making market.

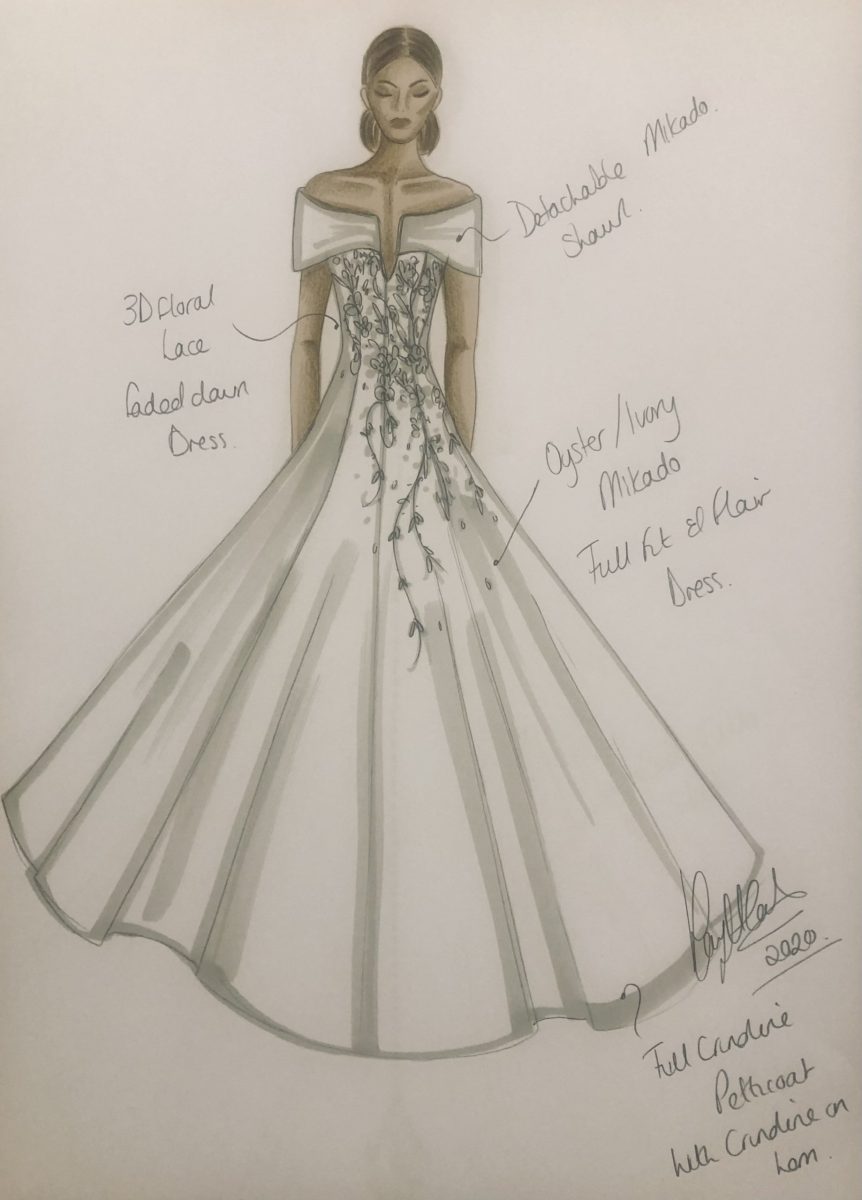

Kay will sketch out designs with good old-fashioned paper and a pencil, getting all her ideas flowing before deciding on the styles she likes best and wants to adapt further.

From here, a final design is established and then this is turned into the final design artwork, as seen below in the original sketches of both our Rebecca and Olivia gowns with their matching capes.

The working drawings:

All the designs that have been selected then have to be translated over to what we call working drawings, which are very different to fashion sketches and illustrations. The illustrations are there to create an overall visual of the design, but they are not easy for the production company to follow as they don’t contain the vital information regarding seams, fastenings or style lines. The number of fabric layers and in what order are also vital, including the linings, and the bodice structure, so the working drawings are often the most important aspect to ensure the final piece is nothing less than perfect.

We have chosen to follow the design journey of our beautifully classic Olivia dress with the matching cape. A timeless fit and flair, A line dress with the simplest of embroidered lace on the bodice and off the shoulder detail. Below you can read on to find out all the in’s and out’s of such a complex production process.

The working drawings for any design are normally black and white drawn free hand or on a computer for more precision. Every detail such as the interfacings used to give structure to a fabric, structure techniques using boning and where the shape needs to be, are all things that are presented in a working drawing. Even down to the length of the train and where all the embellishments and lace details are to be placed.

Olivia’s shape was fairly simple and classic but Kay was quite specific on how she wanted the off the shoulder detail to look with the cut of the neckline.

This process can take hours to complete but will minimise problems and questions from production during the manufacturing process.

Our designer Kay has worked as a seamstress all her life from leaving fashion college, building up a knowledge to present day of over 20 years in dressmaking. Setting up her own Bespoke dress making business at the tender age of 20, she relays all the method of construction and working drawings herself to the factory with her wealth of experience and knowledge.

The production process starts:

Once the factory has all the information from Kay, the patterns are produced using a Computer Aided Design soft wear. (CAD) These paper patterns are then pieced together and placed on a mannequin to be approved by Kay. Kay produces spreadsheets for each design and logs all dates that items are approved and notes that are needed for adjustments. Nothing is missed so there is no mis communication between designer and manufacture at any stage.

Once the paper pattern has been approved, the factory then starts to make the dress in the chosen fabrics.

Kay wanted the detail on the Olivia dress to look like embroidery rather than just a motif or all over lace, so each section of this lace was precisely cut and pinned into place, to look like it was delicately faded down the skirt following the shape of the dress and emphasising the body. The cut of dresses, if gotten right, and add so much shape and illusion to the wearer, so clever lace placement can make or break a design.

Sections of the dress are made, the bodice, then the skirts, and throughout the process, the constant communication between Kay and the factory makes the production run smoothly and efficiently.

Final product:

Once the dress has been completed, the factory sends the final images of the dress on a factory mannequin for approval. Here we have the final factory images or the finished dress and cape alongside the design and paper patterns to see the similarities are kept consistent throughout the process. It’s hard to design a dress but it’s even more tricky to make it look as nice as the original sketch, which is a piece of artwork really.

Any final tweaks or additions will be made before the dress is then sent the Perfect Bridal HQ for quality check.

Time for a photoshoot:

This is when the fun really starts for us, to get our hands on the final dress and see it first hand from a sketch to something we can feel and see on our model Dee. This is when the design really comes alive for us and the final images from the shoots can be used to promote the product in the best possible way.

We also get to see how the dress moves and sits when on a real body, and it’s never too late, even at this stage to make changes if a design isn’t working well, or there are areas of improvement needed.

It’s a hugely exciting process, though presured at times, as we really focus on the best quality, but seeing something, anything taking shape from a drawing to reality is a process designers live for. Any designer can go through a process during the development stages where they lose that spark that ignited when first drawing out ideas, but then it is re-ignited once we get close to the final stages of seeing it for ourselves, and it’s a process that is often overlooked and not seen at all, but makes a product all the more believable and special to the person who is buying it.

We hope you enjoy reading this blog and sharing the journey of our design and production process as much as we do, giving you the reader an insight into our world, that is pretty ‘Perfect’ if we say so ourselves.

Love Team PB x